Email us

Call us

01829 760000

Guide to Security Tape

Security Tapes are used across logistics, in pharmaceutical / labratory companies as well as in general industry, most often as a tamper-evident box tape to provide security and chain of custody through supply chains. In this guide we provide an overview of the types of security tape available, the range of customisation options, as well as the types of applications security tape is most used for.

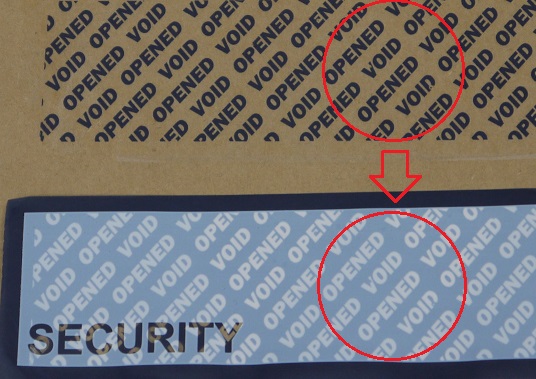

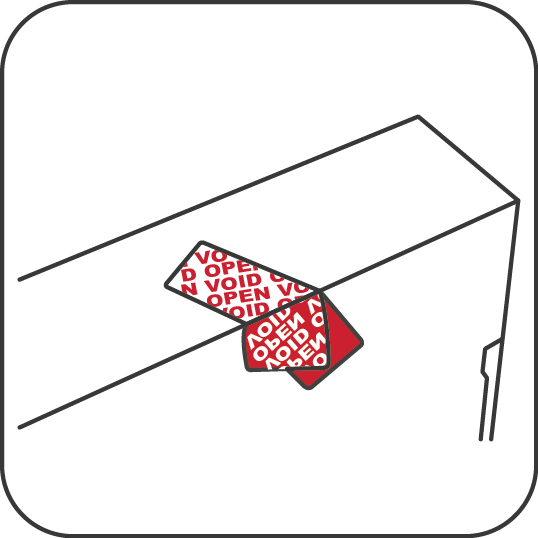

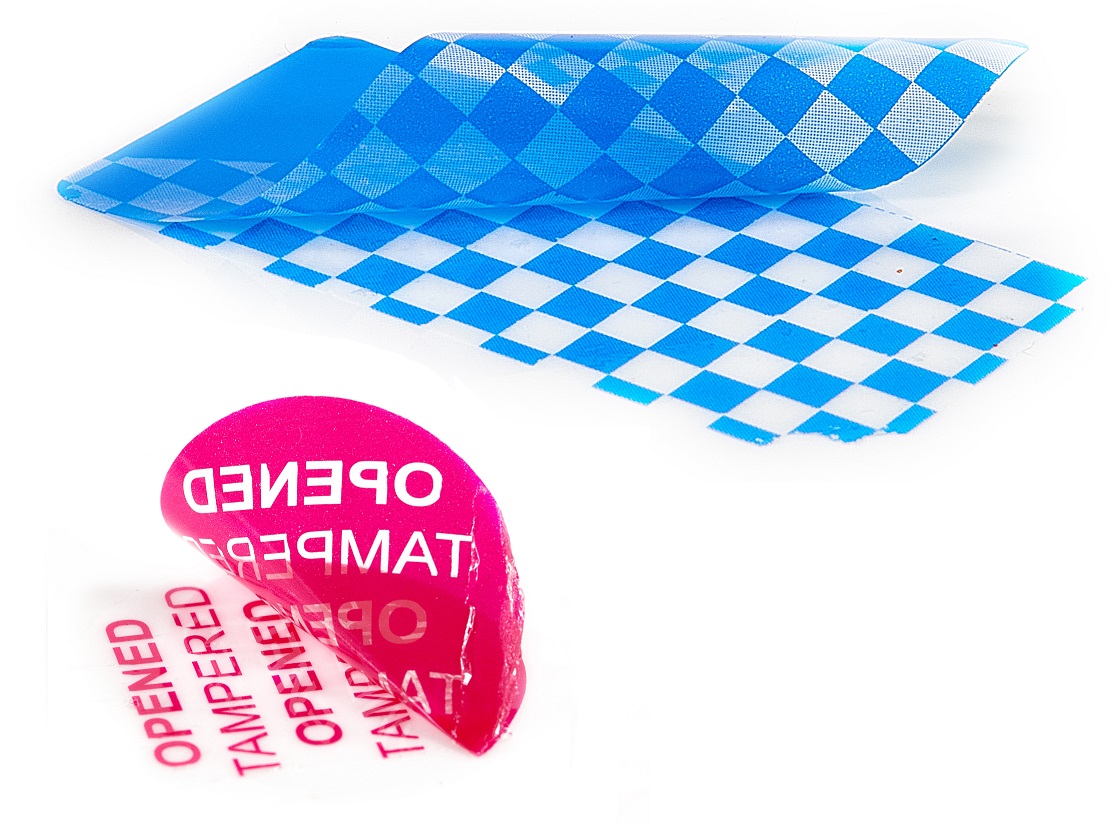

Security box sealing tapes are manufactured with specialised films and pressure-sensitive adhesive, capable of revealing a ‘void message’ on sealed surfaces (such as crate and carton surfaces) upon removal; they can even be used on metal and plastics, for example for security of shrink-wrapped pallets and for sealing cargo containers used in secure airfreight shipments. Upon removal the security box tape the film will also ‘delaminate’, causing the void message to also be shown through the film itself – meaning that opening or tampering is obvious even if attempts are made to stick the tape back down.

Void Message shows through the surface of the security tape as well as in the void message left on the sealed surface

Understanding the Types of Security Tapes

Security tapes are supplied in different formats and styles, and it is useful to understand the distinctions so that you choose the most appropriate and tamper-evident solution possible for your application.

Key Distinction: Overt and Covert Security Tapes

| oVERT sECURITY TAPE | CoVERT SECURITY TAPE |

|---|---|

|  |

'Overt’ security tape is so-named because this type of tape clearly and ‘overtly’ notifies the handler of the sealed package that security measures have been implemented; this can help to discourage tamper attacks or inappropriate handling in the first instance, due to the risk of identification or disclosure. | 'Covert' security tape has been designed to look like a normal box tape until it is removed; only then do security void messages appear underneath. Covert tape is useful to highlight vulnerabilities in your supply chain, and to trace under whose custody cartons are being opened or tampered with. |

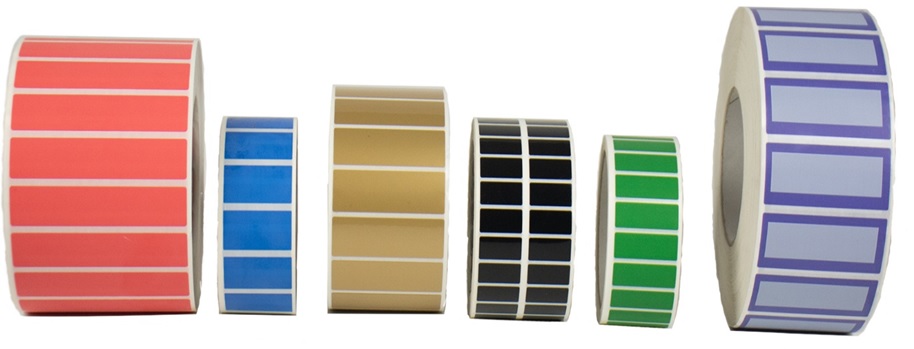

Key Distinction: Continuous security tape vs perforated tape

| Continuous Security Tape | PERFORATED SECURITY TAPE |

|---|---|

|  |

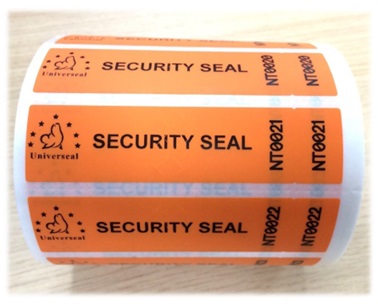

Continuous rolls of security tape are the simplest form of security tape. Security tape is often produced in similar reel formats to standard packaging tapes, e.g. 48-50mm width x 50-66metre long rolls. They can be used in traditional tape dispensers, making them easy to apply to cartons, boxes and so on. | Perforated security tape is generally considered a more secure form of security tape compared to continuous rolls. This type is supplied in segments, typically 10-15cm in length. Each segment has its own sequential security number, meaning that you can seal your cartons or pallets with a particular range of security numbers, for checking against packing lists, manifests etc. |

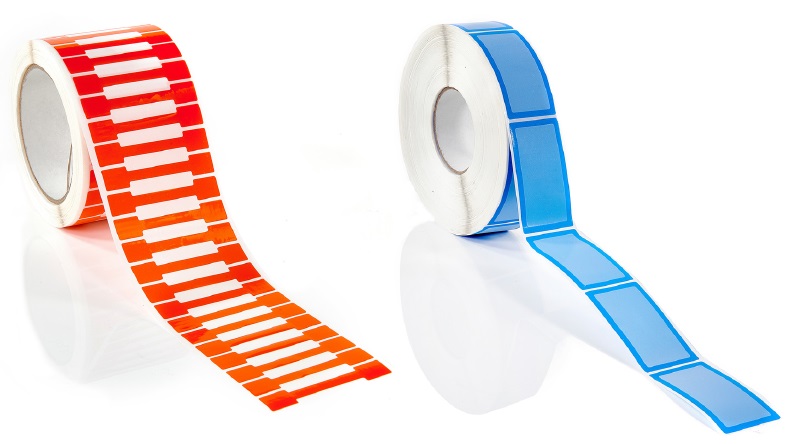

Key Distinction: Standard vs Customised Security Tape

| STANDARD SECURITY TAPE | CUSTOMISED SECURITY TAPE |

|---|---|

|  |

Standard security tapes are available widely, and can be preferable in scenarios where you did not wish to ‘broadcast’ that a sealed consignment relates to your organisation, brand etc. Branded security tapes can sometimes unwittingly notify fraudsters or thieves of which consignments contain higher value or desirable cargo or goods. | Customised security tape can be supplied with bespoke designs, colours, widths, lengths, and surface and sub-surface prints. Customised security tape can convey brand messaging as well as promote security… Bespoke security tape gives your packaging a ‘premium’ and bespoke feel, particularly for consumer apparel, fashion and electronics. For additional security, it is particularly useful to ‘hide’ security information in the sub-surface void messages – the full customisation options are noted below. |

Key Distinction: Plastic versus Paper Security Tapes

| PLASTIC-BASED SECURITY TAPE | PAPER-BASED SECURITY TAPE |

|---|---|

|  |

| Plastic security tapes continue to be very popular due to their high-tack, water-resistance and bright colours. Our plastic security tapes are manufactured from 30% recycled content plastics and can be readily recycled at end-of-life. | A recent and exciting innovation, paper-based security tapes are sustainable, high-performing and secure. The 100% paper-based tamper-evident tape performs well even on rough and uneven surfaces, and have unparalleled sustainability – reducing your plastic use to 0% and with zero packaging waste per roll. |

Tamper-Evident Box Tapes: Customisation Options

There are countless ways in which your security tape can be customised to suit your application. Bespoke security tape, particularly manufactured with bespoke surface and sub-surface prints, can increase the tamper-evident capabilities of your security packaging, making it more difficult for counterfeiters to replace packaging without leaving obvious signs of tampering.

Below are just some of the customisable features which we can assist with: -

| FEATURE | DESCRIPTION | ILLUSTRATION |

|---|---|---|

| Customised surface prints | Custom printing on the surface of your tamper- evident tape can incorporate your company or brand logos, corporate colours, and other application- or product- specific branding. It can also be used to convey information to users about opening the package - for example that product returns may not be valid if security tape is voided. |  |

| Customised sub-surface prints | The “sub-surface print” is what appears on the sealed surface (i.e. carton, crate or pallet surface) when the security tape is removed… This can be a custom void message, QR Coding, Barcoding and more… Custom messages increase the security of your packaging and can convey bespoke operational or user information for your benefits within your supply chains (including traceability – see next feature). |  |

| Customised Traceability | Unique security numbering in multiple formats (including barcodes, data matrices etc) can be printed onto to the surface or even printed into the sub-surface void message itself. Being able to security seal your cartons and packages with your own bespoke security number ranges can greatly increase traceability and audit control within your supply chains, allowing to identify vulnerable shipments and weaknesses. |  |

| Custom Roll Widths and Lengths | We are able to supply security tape in customisable widths and lengths. Tapes can be produced in widths from 25 – 240mm, and in reel lengths between 10 and 600metres. Specific roll lengths can prove particularly useful for applying a consistent quantity of security tape for each cargo consignment – for example, our 20metre reel pallet security tape provides an appropriate amount of tape to seal a shrink-wrapped pallet consistently each time. |  |

| Complex Colour and Design Options | We can print security tapes using the CMYK colour process (CMYK – Cyan, Magenta, Yellow and ‘Key’ (black)). The mixture of these colours can provide complex and visually appealing security tape designs. |  |

Applications of Security Tapes

Security tapes are used to seal boxes, crates and pallets and many other types of enclosures. Security tape is most commonly used for tamper-evident security for sealing of cartons, pallets and packages in the logistics supply chain…

| SECURITY TAPE ON PALLETS | SEALING CARTONS AND CRATES | GENERAL PACKAGING SECURITY |

|---|---|---|

|  |  |

Due to the critical nature of maintaining the integrity and tamper-evidence of sealed enclosures, security tape is used particularly in the pharmaceutical, food & drink and consumer electronics sectors.

View our Range of Security Tape and Security Labels

Top 10 Applications for Metal Cable Seals

We have put together the Top 10 Use Cases for Cable Security Seals, and explain in each case why cable seals are particularly suited for these types of applications.

Cable security seals are flexible and strong types of security seals popular across all types of industries, including freight and transport, food & pharmaceutical, industrial and manufacturing and other sectors. We have put together the below Top 10 Use Cases for Cable Security Seals, and explain in each case why cable seals are particularly suited for these types of applications.

Top 10 Use Cases for Metal Security Seals

| Use Cases of Cable Security Seals | Illustration |

|---|---|

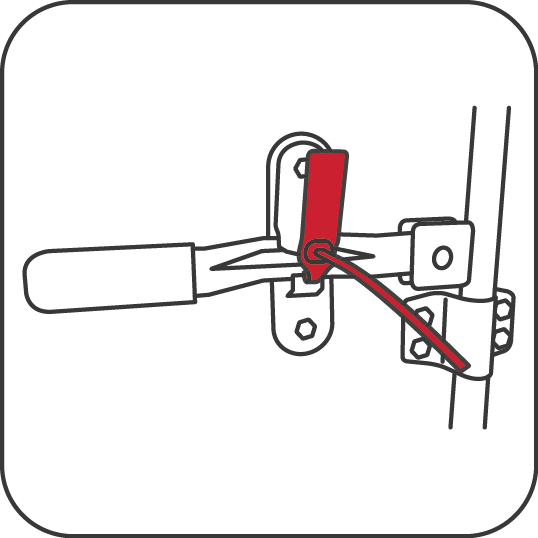

Road Haulage / Trailer Security Cable seals are often used to lock through the locking hasps of road trailer doors, as a stronger solution and more tamper-evident solution than easier breaking pull-through or fixed length trailer seals which can be used alternatively. Our flexiGrip 150M seal is a HMRC Customs accepted seal, and road freight transiting the UK-EU customs borders can utilise customs-accepted cable seals as a cost-effective security seal solution for cross-border road shipments. |  |

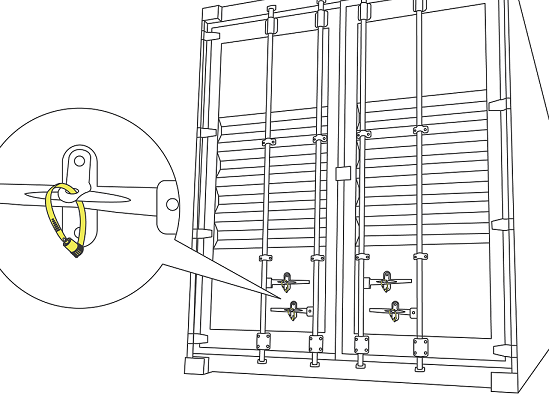

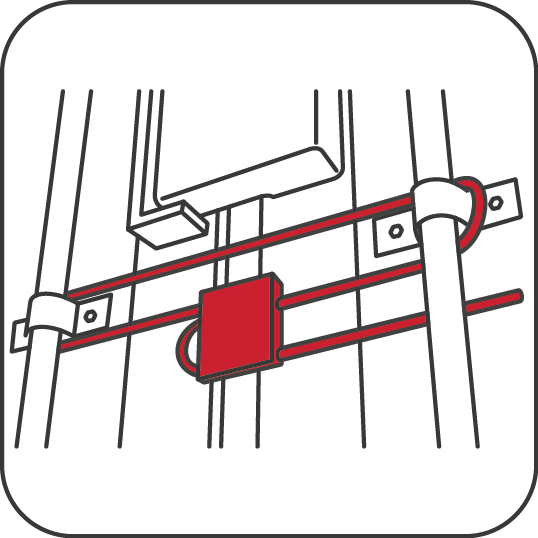

Shipping Containers ISO17712 High Security Cable seals are strong barrier seals suitable for sealing of shipping containers transiting customs borders. Cable Seals are sometimes preferred to more conventional bolt seals for shipping containers to provide increased security, particularly for high value shipments involved in food/drink and pharmaceutical logistics: i. Extra-long cable seals can seal around the vertical locking bars, which can provide superior security compared to sealing at locking hasps ii. Our specialised double-locking Flexigrip 500MD is a heavy-duty cable seal which provides a double locking mechanism, for increased security shipments. |  |

Air Cargo Containers Air cargo containers are often subject to vibration, knocks and shocks during air transport and ground movements, and as such lower-strength plastic pull-through seals are not often strong enough to provide effective tamper-evident security. Cable seals provide higher strength security to ensure that seals do not open whilst in transit, providing a full chain of custody of sealed air cargo enclosures from point-to-point. |  |

Rail Cars Cable seals are ideal for sealing individual rail freight car doors. Our range of cable security seals have rugged design features to ensure chain of custody during rail freight movements. |  |

Intermediate Bulk Containers (IBCs) Light-weight cable seals with smaller apertures, for example 1.5mm cable diameters (100S and 150M Models), are suitable for sealing through apertures in Intermediate Bulk Container outlet points. Cable seals seal IBC’s against unauthorised or illegitimate access and maintains the chain of custody of full and empty IBC’s whilst transiting through the supply chain. |  |

Postal and Mail Sacks and Bags Cable seals are well-suited as high-strength pull-through security seals, where the application in question demands increased strength or tamper-evident security. For example, mail sacks might contain particularly sensitive items or cargo requiring the additional strength and tamper-evident protection of cable seals. Cable seals can withstand over 2000KgF of pulling strength force (depending on model) and will not break in transit accidentally. |  |

Bulk Tanker Hatches, Manholes and Valves Chemical and fuel bulk tankers often have multiple points of access, and cable seals are an excellent way to seal these points of access so that legitimate users can maintain an audit and chain of custody of when, how and where tanker contents have been accessed. |  |

Open Top Barrels and Chemical Drums Cable seals can provide a strong tamper-evident lock to sealing the metal clasp mechanisms of open top barrels, ensuring drums remain sealed until delivered to customers, or received back to depots etc. |  |

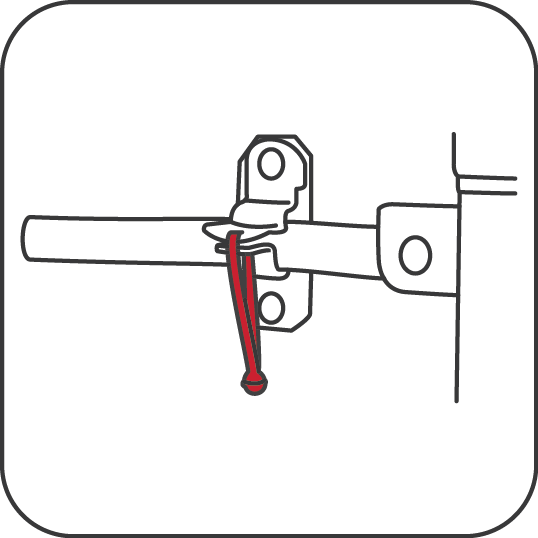

Valve Lockout Cable seals, sometimes known as “car seals” when used in the context of valve lockout applications, can provide a safe and effective way to isolate valves of all kinds, including quarter-turn, 3,4,5-way valves, gate valves, and butterfly valves. Car seals / cable seals can prevent the actuation of equipment, assisting in isolation and inspection programs. |  |

Pallets & Crates Our StrapSecure cable seal and pallet strapping solution is a convenient and cost-effective way to seal the intersection of strapping which can be used to seal pallets and crates being transported through the supply chain. StrapSecure is particularly suited for sealing of APHA agricultural and pharmaceutical consignments, as they provide security on the individual pallet-level. |  |

See our full range of cable seals for more information.

Please contact us at sales@universeal.co.uk or +44 (0) 1829 760000 to discuss your cable seals requirements today.

Display

per page

A Guide to Cable Security Seals

In this article we explore the ‘flexibility of the flexiGrip’ – giving you an in-depth look into our range of metal cable seals used across the world, the benefits of using cable seals for your security, and the wide range of customisation options available to you.

What are Cable Seals?

Cable security seals, also known simply as ‘cable seals’ or wire rope seals, are flexible and strong types of security seals popular across all types of industries, including freight and transport, food and pharmaceutical, industrial and manufacturing and other sectors.

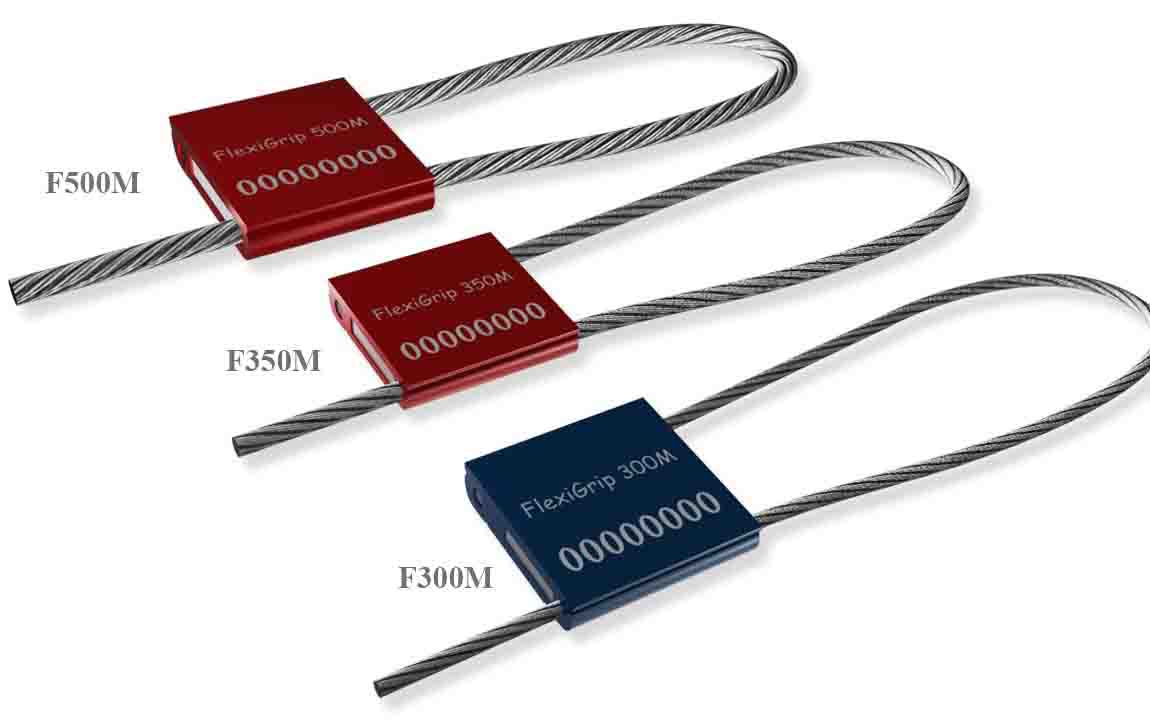

Cable seals generally consist of a metal or plastic body, with the cable / wire rope permanently cinched or clamped at one side of the body, and with a one-way tamper-evident locking chamber at the other end of the body. The wire rope is inserted into this locking chamber and progressively tightened to suit the application. The seal can only be opened by cutting the cable; our cable seals feature non-preformed cable which frays when cut, preventing re-insertion and providing a clear indication of seal tampering.

Why use Cable Seals?

One of the chief benefits of metal cable seals is the combination of the strength and flexibility of the wire cable construction – a cable seal can be tailored in terms of its diameter and length so that it may provide an effective tamper-evident sealing solutions for many applications – from small-scale drums and crates, and all the way through to heavy-duty sealing of shipping containers.

Thinner cable diameters (< 2.5mm diameter cables) are pliable and flexible, and are ideally suited to small-scale applications, whereas heavier gauge 3, 4 and 5mm diameters are much stronger, and can securely seal large-scale sealing applications, such as around container locking bars, or large valve lockout applications.

Cable seals, from lightweight 1.5mm diameter to heavyduty 5mm cable diameter

Cable Seals versus Plastic Seals

Cable seals have much higher pulling strengths than plastic pull-through seals which are sometimes used in their place – some of the strongest plastic pull-through seals might have pulling load resistances of up to 50KgF, but even the most light-weight cable seals are twice as strong as this, and our strongest cable seals (the 325M and 500M) are over 20 to 50x times stronger than plastic seals! This makes them ideally suited to use cases where it is important that seals do not accidentally break in transit, for example crates which are being transported in vehicles.

Security and High-Security Classification Cable Seals

Another benefit of cable seals over plastic seals are the ISO and other national security standards that our cable seals are certified to. The Flexigrip 150M cable seal is certified by the Security Seal Testing Authority (SSTA) as an accepted HMRC customs seal, and for international shipping containers sent by sea freight, our Flexigrip 325M & Flexigrip 500M seals are ISO17712 'H' High Security Classification and C-TPAT compliant - suitable for US customs entry. These certifications make cable seals more suited to customs movements.

Our Range of Cable Seals

flexiGrip cable seals are available in many configurations, including metal or plastic bodies, and in cable diameters from 1.5mm up to 5mm. Below chart provides an overview of our range…

Cable Seal Model | Cable Diameter | Load Resistance | ISO17712 Class | Use Cases |

1.5mm | 101kg | Indicative | Road and Rail Freight, Cargo Trucks, Postal and Mail Sacks, Drums, IBC’s, Airline Trolleys, Drums, Boxes, Cash Bags | |

1.5mm | 259kg | Indicative | ||

1.8mm | 400kg | Indicative | ||

1.5mm | 256kg | Indicative | HMRC Customs, Bulk Tankers, Railway Cars, Valves, Drums, Open Top Barrels | |

2.5mm | 413kg | Security | Bulk Tankers, Valves, Drums, Open Top Barrels | |

3.25mm | 1193kg | High-Security | ISO17712 Customs Movements, Shipping Containers, Bulk Tankers, Industrial Valves

| |

5mm | 2039kg | High-Security | ISO17712 Customs Movements, High Value Shipping Containers, Bulk Tankers, Industrial Valves, Railway Cars, Heavy-Duty Sealing,

| |

5mm | 2039kg | High-Security | ||

1.5mm | 256kg | Indicative | Pallet and Crate Security, APHA movements

|

Customisation Options

| FEATURE | DESCRIPTION | ILLUSTRATION |

|---|---|---|

| Custom Cable Length | We can produce our cable seals with extra-long lengths, such as 2metres. These long length cables are useful for large-scale valve lockout applications, and for sealing around the vertical locking bars of shipping containers and trailer doors. |  |

| Cable Material | As standard we supply with galvanised corrosion-resistant steel – however, for increased corrosion resistance we can also offer in full stainless-steel cable options, particular suited to marine and maritime applications. |  |

| Custom Engraving | Customisation options are endless, including but not limited to :-

|  |

| Colour Customisation | We offer 12 standard colours as standard, to enable customers to take advantage of colour-coding in their operations |  |

| Counterpart Labelling | We can produce cable seals with counterpart labels for duplicate barcode numbering, for application of labels onto paperwork etc. This can reduce possibility for mistakes due to human error / transcription errors. |  |

| ABS Encapsulation | Available on 325M and 500M models, we can produce cable seals with fully encapsulated ABS overmouldings, protecting the laser-engraved anodised aluminimum surface, for the ultimate tamper-resistant cable seal solution. |  |

You can also view our guide to the Top 10 Applications for Cable seals here.

Please contact us on +44 (0) 1829 760000 or sales@universeal.co.uk to discuss your cable seal requirements today.

Types of Container Seals

Most shipping containers transiting around the world will be sealed by way of a High-Security Bolt Seal, and with good reason. Bolt seals are inexpensive but strong barrier seals which cannot be opened except by application of heavy-duty bolt cutters which physically and permanently destroy a security seal, making reinstatement impossible. Bolt seals are required for international customs movements and must conform to internationally agreed standards for manufacturing good practice, strength and tamper-resistance, as stipulated under ISO17712 “High-Security” and C-TPAT Regulations.

However, bolt seals are not the only kind of security seal which can be used, and for certain types of shipments or in particular scenarios it is more suitable to use other types of security seals for sealing shipping containers, and in this guide we explain why this is the case.

| Type of CONTaiNER security seals | illustration |

|---|---|

Bolt seals are the original form of security seal for shipping containers. They are made up of two separate parts which include the bolt pin and the barrel, supplied together and with counterpart seal numbers engraved on each part. Container bolt seals are locked by pushing the pin into the barrel – the barrel has a self-locking system, and once sealed cannot be opened again; a bolt cutter must be used to open the seal, which permanently destroys the seal and makes reinstatement impossible. |  |

The Fork Seal is another type of seal fully-compliant to ISO17712:2013 HSS (high security seal) for sealing shipping containers. Fork seals provide complete wrap-around protection of container locking bars of any size and offers the highest form of container security; the strong steel can only be cut at the designated cutting point using the very heavy-duty bolt croppers. As one of the stronger barrier seals available on the market today, Fork seals are preferred by some users when sending high-value or high-target shipments globally; for example, shipments of whiskey and other high-value food & drink specialities, as well as valuable or sensitive pharmaceutical shipments. |  |

Cable security seals, also known simply as ‘cable seals’ or wire rope seals, are flexible and strong types of security seals. Our higher strength cable seals (>3.25mm diameter) are as suitable for high-security sealing of shipping containers as bolt seals because they conform to the same ISO17712 High Security standards. Indeed, cable seals can be a higher security solution than bolt seals, because their flexible wire construction and customisable lengths mean that they can seal around vertical locking bars, rather than through container door locking hasps/ cams, which can be susceptible to tamper attempts. As long as a cable seal is progressively tightened as tightly as possible then both doors are sealed shut and cannot be opened, regardless of any attacks on locking hasps or locking cams. Additionally, we also supply our double-locking Flexigrip 500MD, which provides two locking mechanisms within one seal, for a superior sealing solution. |  |

Our Globe seal is a robust all metal strip security seal, providing secure protection for shipments in transit, including for sealing of trailer doors and railway cars. It is a reliable and immediate indicator that goods have been received as sent. The seal features a locking mechanism totally enclosed in the head, which is secured by two independent spring rings. The seal is applied without the need of tools and is certified as an ISO17712: 2013 'indicative' classified security seal. |  |

Plastic Security Seals for Shipping Containers Plastic seals are indicative in nature – whilst they provide clear evidence of tampering, they can easily be cut and broken, and so serve as a visual indication of tampering rather than being a barrier to entry. As such, they are often thought to not be appropriate for container security. However, this is not always the case! Shipping containers are not always under customs control; once shipping containers have arrived to port and have been customs cleared, they have entered into free circulation into the domestic market, and are making domestic onward journeys, in a similar way to road haulage trailers. Plastic security seals can then serve as a tamper-evident, easily accessible solution which continues to provide a level of security to the container, without being as heavy-duty or costly as container bolt seals. Another example is using a plastic security seal a tamper-control check on empty containers returning to depots or terminals. Popular models include our DoubleLock seals and FleetLock seals. |

|

Container Locks Keyed Container Locks are the strongest possible types of lock, because they are keyed and are designed to be used many times over many shipping container consignments. Like all keyed locks, container locks have a disadvantage in that it relies upon of appropriate security and availability of the access key; but they do have their uses in particular scenarios - please contact us should you like further information on the types of container locks we can supply. |  |

How to Securely Seal your Shipping Containers

A Guide to Shipping Container Security

One of the worst nightmares for any shipper or receiver of a shipping container: your vessel arrives as expected to port, but on unloading the shipping container it becomes apparent that the security seal used to seal the container is not in the condition expected, and cargo has been interfered with, stolen or otherwise compromised.

In this article we provide some helpful explanation and examples of how you can make sure you select a suitable shipping container seal capable of protecting your cargo; how to apply security seals properly, and other considerations to look out for to ensure security seals provide maximum protection to your goods.

The Rise of Shipping Containers

Containerisation emerged as the standard for global sea freight in the 1970s, revolutionising how sea cargo was handled and transported. Its chief innovation was to simplify the handling of endlessly varied types of cargos – by first packing cargo into discrete, standardised shipping containers suddenly freight could be handled and stacked with ease, regardless of its contents. This helped to greatly increase the efficiency of the global shipping industry and led to a huge increase in global trade. Today, shipping containers make approximately 200million trips per year, and shipping container security has become crucial in protecting global supply chains against fraud, theft, drug trafficking, counterfeiting and terrorism.

But the shipping container introduced new problems… for instance, how could shipping lines keep track of what was in each shipping container? And how could governments and customs authorities be sure that what was in a container was safe and properly declared? How could customers be sure that what they had paid for had actually arrived in tact, and without loss, theft or other mishandling? Record keeping and security had to keep up with the innovation, and the Universeal Group were involved in the design of some of the first generation of shipping container security seals to assist in this aim.

What are Container Security Seals?

Simply put, a container seal is a one-use tamper-evident ‘lock’ for a shipping container door, made to withstand the rigours and harsh conditions experienced during global sea freight, and safeguard the container on its journey. Each security seal has a unique security identification number, and once sealed can only be opened by breaking the seal permanently, making reinstatement or re-use impossible.

Today, security seals are required by customs authorities and shipping lines all over the world as a pre-requisite for the movement of shipping containers. The security seal is a crucial part of shipping container security, and it is for this reason that every shipping container has at least one seal applied before shipping. Container security seals alerts stakeholders to potential theft of goods, reduces fraud and counterfeiting, and minimises the risk of unauthorised access. For this reason, Universeal Group continues to evolve our range of bolt and other container barrier seals to meet modern security concerns and produce hundreds of thousands of barrier seals every year.

Which Types of Security Seals Should be Used?

Shipping containers should only be sealed for international freight movements using "barrier seals": security seals designed to provide tamper-evident security and act as a physically strong one-time ‘barrier’ to entry, delaying intrusion to opportunists who might try to access shipping containers. Barrier seals should be ‘high-security’ classification, as certified to ISO17712:2013 standards. ISO17712 High Security Seals are manufactured to an internationally recognised standard which sets out the tamper-evident and physical strength properties which seals should conform to; for example, they should withstand a tensile strength of over 10kN, amongst other requirements.

It is also important to note that certain shipping lines (Maersk Line, CMA-CGM, MSC etc) have their own particular security policies in place, and when in doubt it is best to check with a representative of the respective shipping line as regards suitability of certain types of seals. Further regulations are laid out in the International Ship and Port Facility Security Code (ISPS) and the US Customs-Trade Partnership Against Terrorism (C-TPAT) program, and the security sealing requirements under these regulations have widespread international adoption.

The Bolt Seal – the Container Seal

Different types of barrier security seals can be used in different scenarios on containers, and we have a guide for this also. However, by far the most popular form of seal is the bolt seal, a barrier seal of pin and barrel type construction, and in this article we focus on this type of barrier seal for international shipping.

Bolt seals are made up of two separate parts which include the bolt pin and the barrel. Both parts should be supplied together and have counterpart seal numbers engraved on both parts of the seal…

|  |

Bolt Seal - pin and barrel | Counterpart duplicate numbering |

You should check that your supplier of security seals marks the serial number on the top of the pin head as shown in the images above… certain suppliers only supply less secure bolt security seals with markings down the length of the pin… this is obscured once sealed… (as below image). If the seal number is obscured, how can you be sure the serial number on the pin actually matches the barrel of the seal, and hasn’t been cut and replaced?

An example of a bolt seal with sequential numbering duplicated along the length of pin - obscured by the locking hasp when sealed in place. If the seal number is obscured, how can you be sure the serial number on the pin actually matches the barrel of the seal, and hasn’t been cut and replaced? Always make sure you use bolt seals engraved with security numbering located on the pin head instead!

Should I Customise my Bolt Seal?

One particular option you may wish to consider is the option to have your bolt seals custom-marked, with a bespoke marking such as your company logo along with custom barcoding or serial number ranges. You can also consider using particular seal colours on rotation, or pre-fix codes for certain kinds of shipments – these types of measures can reduce the ability of fraudsters to replicate seal numbers from blank seals.

How do you Seal a Shipping Container?

Engaging the Seal

Container bolt seals are locked by pushing the pin into the barrel – the barrel has a self-locking system, and once sealed cannot be opened again; a bolt cutter must be used to open the seal, which permanently destroys the seal and makes reinstatement impossible. Slide the bolt through the hole in the locking aperture and insert it into the barrel from beneath the hole. You’ll hear a ‘click’ sound as the bolt fixes itself into the barrel and is secured to the container. Check the seal by trying to pull apart the two pieces – it is not possible to re-open the seal with your hands so you can check the seal is closed by trying to pull the pin and barrel apart again.

A standard container has two doors, each fitted with locking bars with cams which lock into keepers located at the bottom of the container. The locking bars have handles with holes through which a seal can be attached to. The left door of the container is closed first, followed by the right door, so seals should be placed on the right-hand door for security.

Please note also, that you should be careful to only use barrier seals which have an anti-spin design. One of the known methods of defeating supposedly ‘tamper-evident’ bolt seals is by taking advantage of the free play of the pin available in inferior bolt seals – the pin is spun out of the barrel using a drill, allowing the seal to be opened and then re-sealed without signs of tampering. Our anti-spin designs prevent these kinds of attacks, as the pin cannot move completely freely.

Correct Location for Sealing Containers with Security Seals

The best location to seal the container is at the bottom of the right-hand door, where a security cam with a hole through engages into a special locking keeper. This is the most tamper-resistant location for placing of a security seal, and is the preferred location where available on containers with this anti-theft locking device. However, not every shipping container has this type of modification on the cam/keeper arrangement, and if not then the only other location where bolt seals should be placed is on the handle attached to the locking bar nearest to the door edge (i.e. the leftmost locking handle on the righthand door). It is not acceptable to seal the handles on the left-hand door, as the righthand door opens first.

Should I use More than One Container Seal?

There is no fixed rule on how many seals you should put on a shipping container, but every shipping container must have at least one seal located in one of the appropriate places. Technically there could be up to six places where seals can be sealed on a shipping container… It should be noted however, that seals do not actually prevent theft and pilferage – a committed thief with the appropriate tools can cut six seals just as easily as one!

Sealing and Recording Security Seal Use

If you are the sender of finished cargo loaded into FCL containers, and you are in a position to do so, we would always recommend that an authorised member of your team is present when the container doors are locked and the seal is applied – an image with time/date stamp can be really valuable in the event of discrepancies. Sending this image to the consignee is always good practice. Additionally, and particularly for LCL shipments, we would suggest that you ask your freight forwarders to send pictures of the seal (with seal number visible) on the container once sealed, again affixed with a date/time stamp. Such images can become very important in the event of loss or damage to cargo, as they can demonstrate to surveyors and insurance companies of the best practice of the parties to the insurance contract, and help them to determine the veracity of the claim.

Port and Customs Requirements for container seals

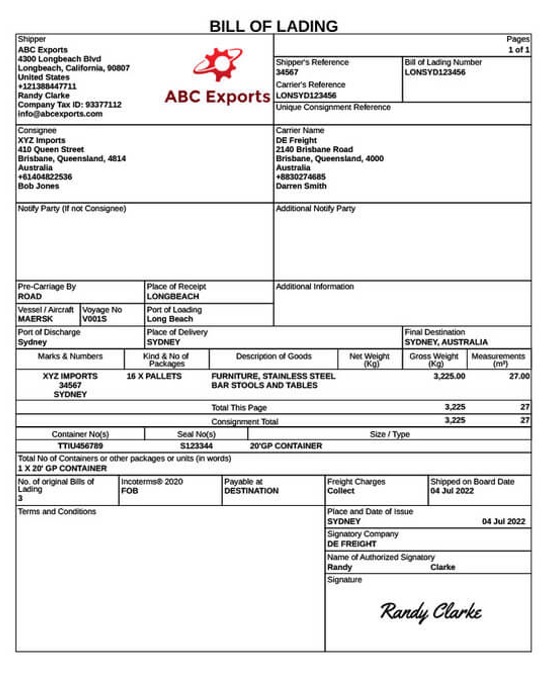

Shipping Lines and Bills of Lading

Shipping lines will only accept shipping containers for freight movements passing through customs borders with at least one container seal. The corresponding seal should be clearly noted on all road manifests, waybills and/or Bills of Lading to minimise the risk that shipments are delayed through the customs process. Bills of Lading provide key information about each shipping container movement, including shipping line, third parties, container ID number, weights/ classifications of contents, and also the seal number. As an interesting aside, it is thought that the very first Bills of Lading appeared for the first time in Spain, as early as 1544! An example Bill of Lading is shown below for illustration...

Customs Agencies and Security Container Checks

The Customs Department of respective national governments have the authority to conduct checks and random inspections on shipping containers passing through their jurisdiction at any time. During an inspection, any trader or freight forwarder security seal previously applied will be broken, so that the container and its contents can be checked against lodged customs paperwork and any discrepancies.

Once inspection is finished, it is likely that a prescribed ‘customs seal’ will be placed to re-secure the shipping container and to keep the contents safe on its ongoing journey. If you see an official customs seal applied to your container you know that your shipping container has been checked by customs authorities, rather than providing an indication that tampering has taken place.

If discrepancies or other issues with the shipping container has been discovered by customs authorities, they may apply one of a number of remedial steps in order to address the situation, which will depend precisely on the nature of the breach. It is important at this stage to take on board all of the customs authorities’ demands or requests, which may include deviating freight to onward freight handling terminals for further investigation, requests for additional customs duties, or other remedial action.

How Do You Remove a Container Seal?

It is suggested that the following steps are taken on receipt of a shipping container to ensure that no tampering has taken place:-

| step | DESCRIPTION |

|---|---|

| 1 | Before removing the seal, check for any signs of damage or wear or tear. In particular, check seal number engravings – are all characters uniform in size; are they are any signs of abrasion to the plastic on which markings are engraved; does the seal number on the pin of the seal correspond exactly to the barrel seal number? |

| 2 | The seal number on the container should obviously correspond to the bill of lading number and any other shipping documents presented by shipping lines or freight forwarders. If not, this discrepancy should be immediately raised and investigated with the shipping line. |

| 3 | If there is any evidence of tampering whatsoever, it is recommended that the seal should only be opened once the shipping line, freight forwarder and/or insurance representatives are present so that agreement is reached by all parties on the appropriate course of action. |

| 4 | If you see a customs seal on your container, you know that it has been opened by customs representatives, which is within their authority. You should follow any remedial steps that are requested in full to be compliant with local relevant regulations. |

| 5 | Container seals should be opened using bolt cutters of appropriate strength and size – the seal should be cut across the length of the pin. It is recommended that protective eyewear is worn for this operation, as the forces applied on cutting a seal are large and debris from the seal can be released at high velocity, causing potential injury to vulnerable parts of the body. |

What Should I do if My Container Seal is Broken or Missing?

A broken container seal indicates that cargo and goods inside the container may have been tampered or interfered with. If your container arrives with a broken or no seal, you should immediately contact the shipping line and their insurance company, for further investigation and a potential claim for compensation due to loss or damages pursuant to the any breach of contract.

If you do believe that you have been victim of a potential unauthorised tampering or interference attack, the best course of action is to act thoroughly and promptly:-

| STEP | DESCRIPTION |

|---|---|

| 1 | Take photos of the seal (if any) and the shipping container. |

| 2 | Immediately contact the shipping company, your freight forwarder and the company with which you have contracted your maritime transport insurance immediately. |

| 3 | Do not open the container until a representative of the shipping company is present. |

| 4 | Once the container has been opened, be sure to continue taking photos of the contents. This is very important in case you want to file a claim against the shipping company. |

If you found this article useful, please share with your colleagues and members of the shipping industry. You can also view all Container Security Seals in our range here, including our High-Security Locktainer 2020 Bolt Seals.

Types of Security Seals

The range and different types of security seals and tags can be confusing to the uninitiated, so we have produced the below quick visual guide for understanding some of the key differences, and how particular types of security seals might be suited to use cases in your organisation. For further help and assistance, please contact us at sales@universeal.co.uk

| .png) | .png) |

| Plastic Indicative Seals, 2 types: (1) Pull-Through Seals seal through locking chamber & pull progressively tighter, suitable for sealing of mail & cash bags; (2) Fixed Length Seals form a fixed loop, suitable where over-tightening might cause accidental breakage in transit (such as trailer hasps). | Security padlock seals are fixed length seals which are small and suitable for sealing of small enclosures like trolley apertures, first aid and other equipment kits, security bag zippers etc. They can easily be sealed and broken by hand for quick and convenient application. | Bolt security seals provide barrier control for shipping containers. They consist of a counterpart barrel and pin with duplicate numbering, sealed together and requiring bolt cutters to remove. They must meet ISO17712 high security standards and are suitable for cross-border customs movements. |

|  |  |

| Metal Cable seals are strong barrier seals, and in their heavier gauge options (Flexigrip 325M and Flexigrip 500M) are also ISO17712 'High Security' approved for customs movements. The pliable wire cable can be flexibly used to seal through hasps and around vertical locking bars, providing increased security. | Metal strip seals are useful option between plastic indicative seals and heavier duty cable and bolt seals - they provide a higher tensile strength of between 50KgF - 100KgF compared to plastic seals, but are most cost-efficient compared to cable and bolt seals. Their thin straps make them well-suited for sealing small apertures, such as TIR cords and railcars. | Meter wire seals are products suited to sealing utility (gas and electric) & taxi meters. They range from simple plastic and metal seals which can be crimped onto sealing wire with pliers, to more sophisticated self-locking seals with inner mechanism. Wire seals are produced with narrow gauge wire to fit through the small apertures of meters (<1mm). |

|  |  |

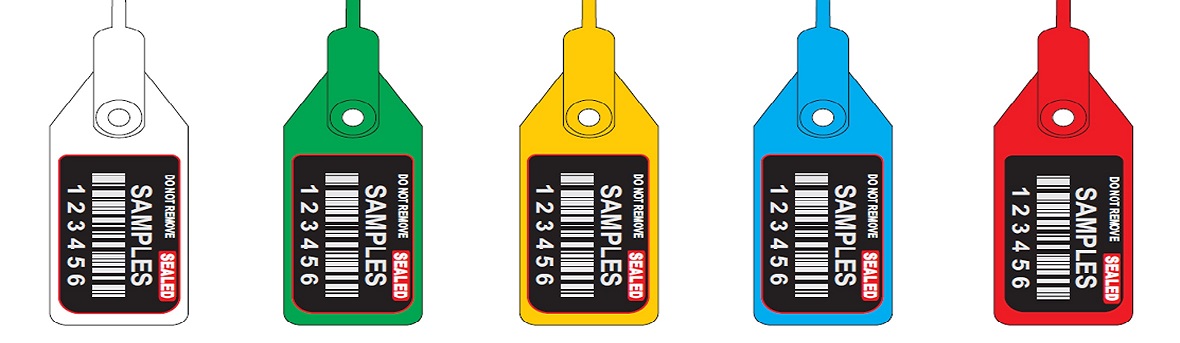

| Tote box plug seals are a specific type of fixed length seals designed to securely seal the lids of attached lid containers (ALC's) firmly shut. Plug seals seal down flush on to lids, making stacking of tote boxes easier, and can also be produced with paired numbering to seal both of end of the crate with the same security number. | Security labels and tapes are their own category of security seals which work on the basis of their tamper-evident film and adhesive properties, rather than by mechanical anti-tampering. By their nature, they are suitable for sealing flat surfaces, such as carton and pallet seams and edges. | Electronic seals are their own subset of security seals which use electronic sensors to detect a tamper-evident state. They are generally reusable seals with a higher initial cost which is spread over many thousands of uses. |

Security Protocols - Making Security Seals Work for You

Security seals can help to protect your cargo, valuable assets and confidential items. They serve an important role in loss prevention through reducing the incidences of theft, fraud and lost goods. Every year, hundreds of millions of pounds of valuable cargo is lost in such ways – and seals are one way in which these losses can be prevented at a tiny fraction of that price.

However, your cargo and your business are only protected properly when security seals are used as part of your wider supply chain, and due consideration has been made to the complete security of your logistics operations. Most risks which security seals are designed to mitigate – theft, pillage sabotage, smuggling etc – are human behavioural issues, and as such just as much attention should be paid to the humans involved in your security processes as to sourcing the appropriate seal itself.

No matter how well a security seal has been designed, seals only work if you have security at both ‘ends’ – at the point of sealing and at the point of opening – which in turn relies upon the security and reliability of your people. This goes to the very complex issue of organisation’s values and management systems, and how these are communicated to everyone working in the organisation. This of course goes beyond the scope of security seals, but what we can do below is to outline useful pointers to consider when setting up your protocols for security seals and how they fit into your wider supply chain.

Onion Skin Security

The ‘onion skin’ principle is very useful when considering security measures – the idea being that an organisation should have a layered approach to security, so that if one security measure fails, then another will not. For example, consider combining security seals on a larger enclosure such as trailer doors, with security labels on smaller enclosures, such as pallets of cargo or even individual cartons of product.

This can apply not only to physical layers of security seals, but also in security methodologies applied. For example, CCTV in areas where seals are stored, sealed and opened will help you to identify suspicious activity or instances where personnel are not following agreed security protocols.

Custody of Seals

Consider this question: which individual within your organisation is responsible for the purchase of security seals? What would happen if a bad actor within your organisation ordered “copycat” seals for their own nefarious activities and started to use them... would you have systems in place to identify this? Are you using a reputable manufacturer of security seals who have systems to help? This is to illustrate the point that even before security seals have arrived on site, you need to be mindful that seals can be a target for fraudsters. Security seals can act as a false positive that all is well with consignments, and therefore are of value to individuals attempting to hide tampering. The risk increases once seals have arrived to your location, where they are at physical risk of interference. Would you notice if a box of seals was taken by an opportunist?

To minimise risks, security seals should be stored in a secure storage area, ideally with limited access by senior members of your team, and covered by CCTV to pick up any out of the ordinary circumstances. It is recommended that particular seal number ranges are allocated and distributed to designated teams in appropriately sized batches, as necessary for your operations. This can provide a tight audit trail and help to identify vulnerabilities as and when seal tampering / anomalies arise.

Keeping Track of Data

Allied to the above is the importance of recognising that seal numbers are important data which should be collected, collated and stored in a secure way as would be the case with any other type. Keep a controlled record of security number ranges being dispensed out and account for every seal being applied using a documented system.

Using barcoded seals can be useful and is increasingly common. Barcodes can be integrated with barcode readers on PDA’s for automated incorporation into your processes, and reduces the likelihood of human error. If you are using a paper-based system (as is still common for road manifests and bills of lading), make sure that a consistent process is followed, and make copies for archival where appropriate. Consider using seals with duplicated barcode labels on the reverse, which can be simply applied to corresponding manifests / paperwork, rather relying on rewriting or rekeying seal numbers.

Variation

Our seals are highly customisable and can be produced in different colours and with different markings – we can print QR codes, data matrices, logos, barcodes, and many other types of information. Consider using a system of colour or marking rotation, be that on a periodic rotation basis, or using different marked seals for different operations or teams.

Seal Checks

It almost goes without saying, but physically checking seals for tell-tale signs of interference is all-import for the integrity of your supply chain. Fraudsters are ingenious and will try many ways to defeat seals. We produce a ‘known methods of intrusion’ document, available to Universeal UK customers, which can help you to recognise and train your staff in the ways that bad actors attempt to circumvent security seals. Please speak to your Account Manager for further information.

Staff Training and Escalation

Loss prevention and security protocols can only ever be as good as the team implementing them, and efforts need to placed into educating appropriate staff members on the correct way to handle, seal, open and dispose of seals appropriately. Once trained, there should be formal repercussions for failing to report issues with seals as they arrive, for example a failure to report mismatched seals on consignments, anomalies, failures to apply seals, and so on. A system of escalation should also be implemented – if particular members of staff are engaged in a pattern of behaviour or regularly failing to adhere to protocols, this should be flagged and reported to senior levels of management for investigation.

Stay Up-to-date with Legislation

Legislation does and has changed over the last few years, and we recommend using reputable security seal manufacturers who have been long-established and are well-acquainted with industry requirements. Universeal UK is a participating member of ISMA (the International Seal Manufacturer’s Association) and also in the ISO committee responsible for seal standards. We are at forefront of the development of security seals and tamper-evident packaging. We regularly post updates about developments in the field and best practices to our customers, so that they can ensure they are using security seals appropriately.

We hope this guide has been helpful... read on for a full of glossary of terms! Contact us to discuss your security needs today – email sales@universeal.co.uk or call us on +44 (0) 1829 760000.

This article is the third of four, looking at how security seals can fit within your wider security protocols. View Series below...

- What are Security Seals?

- Choosing the Best Security Seal for the Job

- Security Protocols: Making Security Seals work for you

- Glossary – Understanding security seal terminology

Choosing the Best Security Seal for the Job

With the range and breadth of security seals on the market, it can be very challenging for the uninitiated to know which seal to choose to best suit their needs. From the outset, it is recommended that the decision-maker considers the purpose of the security seal in relation to the application. Considering some of the fundamentals from the outset will help to select the right seal for the job…

…why is the user sealing the enclosure in the first place? Is it for loss prevention, safety purposes, product integrity, brand assurance...?

…what type of goods will be protected? What is the value of the goods?

…where is the seal going, and how? Cross-border shipments are subject to customs regulations which will affect the seals that can be used

…what kind of resistance is required? What are the consequences should if the security seal has been broken or tampered with?

…what environment is the seal being used in? What is the operating temperature? How long does the seal need to last for?

Answers to these questions will have a bearing on the material, form, shape, strength of the most appropriate security seal.

It should also be noted that a security seal alone cannot provide an iron-clad guarantee of integrity. No manufacturer anywhere in the world can say with complete certainty that – given enough time, appropriate circumstances, resources, skills and ingenuity – their security seals are undefeatable... but this is also true of safes, door looks, padlocks and alarms. Security seals should always be used as one layer within an ‘onion skin’ of security (view our guide to security protocols).

With this said, below we note some key characteristics of seals you should consider when choosing the most suitable. Try out our handy filtering tools shown on our main security seals category to find a product matching your needs.

| Seal Feature | Considerations |

|---|---|

| Design Type | Seals come in many forms... Pull-through Security Seals, Fixed-Length Security Seals, Security Padlock Seals, Barrier Seals (Cable Seals and Bolt Seals), Wire/Rope Meter Seals, and even Reuseable Electronic Seals. Security seals also include security tapes and labels, suitable for flat surfaces and edges on enclosures such as crates, cartons and pallets. Each type is designed for particular types of applications - for more information, see types of security seals. |

| Physical Fit (Diameter, Length and Flag Size) | Each security seal will have a particular tail or hasp diameter, an effective useable length, and a standard flag size for visibility of printed identification markings. Narrower seals are useful where seals must fit into smaller apertures, and for this many of our pull-through seals have smaller diameters, such as the MiniLock 570's 1.4mm tail thickness and UniTite 414's 2mm thickness. We also offer extra long seals, such as the UniStrap 412-XL (overall 51cm length) and UniTite 413 (overall 49cm length). In terms of flag size ("marking area"), we offer specialised security seals such as our UniFlag Security seal, which has a large format (108x56mm size). |

| Material | Common materials in use for security seals are polypropylene, nylon, aluminium and steel. Polypropylene is a popular choice for pull-through seals, as it offers a combination of strength, flexibility and wide operating temperatures. However, all types of plastic do become brittle at increasingly low temperatures, and do degrade when exposed to UV light, long-term saltwater exposure, solvents etc. Metal aluminium and galvanised steel cable seals provide more durability and strength where circumstances dictate, and we can also specify stainless steel cable grades for most demanding applications: see our Flexigrip 150M and Flexigrip 325M models. |

| Strength | Seals are specified for particular strengths – for certain applications such as fire extinguishers, kit bags and first aid trolleys it is desirable to have a very low break-strength so that seals can be broken in an emergency – for others, for example mail sack security seals, it is important that seals with strong break strengths are used so that bags do not burst open when under tension. There is a wide range of tensile strengths available, from 5KgF all the way up to 2000KgF, so understanding the possible forces relevant for your application is important for specifying the right kind of seal. |

| Level of Tamper-Evidence | We categorise our security seals as having either a Low, Medium or High degree of tamper-evidence, based on design and construction features, method and material of construction, and level of certification. |

| ISO Classification | Linked to the above, higher levels of security seals are often required for international freight movements - in particular, High Security Seals as classified under ISO17712:2013 regulations for international shipping container and freight movements. |

| Removal Method | Some applications require easy-access into a sealed enclosure, and for this we have security seals that can be removed easily by hand, either with low-break strengths (see our Fireseals) or tear-line features (see our Tracewaste Tear-Off and UniStrap 412LT). For other requirements, security seals need to be robust and should not be removed intentionally without simple tools such as scissors or tin-snips, such as our UniTite 413. In other scenarios, particular for barrier seals, we have our heavy-duty cable and bolt seals, products such as our Flexigrip 325M, Flexigrip 500M and Fork seals which necessitate the use of heavy-duty cutting tools like bolt croppers to remove. |

| Sustainability | Sustainability should of course be at the heart of every business, and security seals should be no exception. All of our plastic security seals are 100% recyclable, and we are increasing options for recycled content and biodegradable security seals on a regular basis. |

Universeal UK has been supplying security seals since 1992, and we are one of the leading organisations in the industry. Please email sales@universeal.co.uk for more information on our range and how we can assist. For advice on using security seals within a wider security program, please continue reading our next article in the series, Security Protocols: Making Security Seals work for You.

This article is the second of four, looking at how security seals can fit within your wider security protocols. View Series below...

- What are Security Seals?

- Choosing the Best Security Seal for the Job

- Security Protocols: Making Security Seals work for you

- Glossary – Understanding security seal terminology

What Exactly are Security Seals?

Definition of a Security Seal

Put simply, security seals provide a tamper-evident chain of custody for cargo and valuable assets in transit or in storage. They are devices that ‘seal’ enclosures to protect them from interference, maintaining the integrity of supply chains from loss, theft and other manipulation. Sealed enclosures can take many forms – including sacks, truck trailers, shipping containers and tote boxes – but what all enclosures share in common is that they encase sensitive items such as goods in transit and are the appropriate point to seal against unauthorised access.

Tamper-Evidence Function

Security seals, when used properly as part of a wider security protocol, serve two key functions. Firstly, they are tamper-evident or tamper-indicating, in that they are designed to permanently demonstrate physical evidence if interfered with – usually by tell-tale signs of breaking or other physical change of appearance, such as a ‘blushing’ on the surface of plastic seals when subject to manipulation or deformation.

These types of seals are sometimes simply called ‘indicative’ tamper-evident seals because their physical appearance indicates their status and that of the sealed enclosure. Indicative seals are easily broken or cut open with readily available light tools such as scissors. Indicative seals are used in many sectors, but commonly used to seal sacks and bags, domestic truck and trailer movements, fire extinguishers, roll-cages and crates.

Access Control Function

Security seals also serve a second access control function, reducing the occurrence of unauthorised access of sealed enclosures. They do this above all by their mere presence – well-placed seals serve as a psychological deterrence to access, simply by making individuals think twice about the consequences and what might happen should they ‘unseal’. Beyond this, a sub-category of seals called ‘barrier seals’ also provide an actual physical barrier to entry, acting like a specialised single-use lock which requires cutting tools to open, such as metal bolt and cable seals. Shipping containers, rail cars, and cross-border truck and trailer movements are the most common commercial uses for barrier security seals. Barrier seals physically prevent an illegitimate opportunist from opening the enclosure easily. These types of barrier seals are frequently referred to as ‘high security seals’ – these are security seals which meet the ISO17712:2013 ‘H’ ‘High-Security’ classification. This is an international standard setting out the strength, tamper-evident characteristics and other manufacturing standards which seals must meet in order to suitable for international customs movements, including US-bound consignments under C-TPAT regulations.

What security seals are not…

It can also be useful to define security seals by reference to what they are not.

Security seals are not just like padlocks. Keyed padlocks – often stronger than seals – are much more expensive, and also much more easily replaced. Unlike a security seal, most padlocks are not uniquely numbered or marked, so they can be broken and replaced leaving no sign that unauthorised access has occurred. Additionally, the key itself presents a problem – keys can be duplicated, borrowed, lost or simply unavailable when needed – and in each case this presents issues. Security seals can simplify security processes because they are low-cost, uniquely identifiable security devices which are designed to be sealed once and then broken once, at the appropriate times.

Nor are security seals just a different kind of cable tie. Cable ties are very different products and are ideal for particular use cases, but they should not be used as a security seal – cable ties can very readily be undone (and thereby re-tied in a matter of seconds…) because they have not been designed for tamper-evidence.

Security Seals Big and Small..

|  |

It is worth noting that security seals don’t come in any one particular form – they can range from simple void security labels or stickers suitable for application on flat enclosures such as pallets or carton seams, all the way up to heavy-duty metal construction container barrier seals...

…As long as it is a tamper-evident device which controls access to enclosures, then it is a security seal!

Universeal UK has been supplying security seals since 1992, and we are one of the leading organisations in the industry. Please email sales@universeal.co.uk for more information on our range and how we can assist. For advice on choosing the right security seal for your particular needs, please continue reading our next article in the series, Choosing the Best Security Seal for the Job.

This article is the first of four, looking at how security seals can fit within your wider security protocols. View Series below...

- What are Security Seals?

- Choosing the Best Security Seal for the Job

- Security Protocols: Making Security Seals work for you

- Glossary – Understanding security seal terminology

Go Green with Our Range of Recycled Content Plastic Seals

Universeal UK is proud to announce that we have now begun manufacturing many of our popular security seal ranges with recycled content plastics, thereby lowering our carbon footprint and contributing to a more sustainable global supply chain.

Universeal is committed to working towards a more circular and low carbon economy, with environmentally friendly security seals which guarantee the integrity of your supply chains whilst not costing the earth.

Initially, our recycled content seals will be available in our Uniflag, DoubleLock, UNI411, UNI412, UNI413, UNI414, UNI415 and UNI416 security seal models. Security seals will be manufactured in special pale-yellow colour to denote its recycled content status, custom-printed to your particular needs, including logo, barcode and data matrix information.

Methodical engineering testing has been undertaken to ensure that recycled content plastic seals have the same characteristics in terms of strength, flexibility and durability as conventional plastic seals manufactured from virgin plastics.

All recycled plastic security seals will be manufactured with a minimum of 30% recycled content, ensuring that security seals are exempt from the UK Plastic Packaging Tax, designed to ensure the widespread adoption of recycled content materials within the UK packaging industry.

Popular models now avaliable in recycled content options are as below:

UNI412 Recycled Content Seals | |

UNI415 Recycled Seals | |

| Uniflag Recycled Seals |

DoubleLock Recycled Seals | |

Our full range of sustainable security seal solutions is shown here - including our recycled-plastic content and biodegradable security seals.

Please enquire via email to sales@universeal.co.uk or call 01829 760000 to discuss your requirements and we should be happy to help.

Security Labels 101 - A Complete Guide

The appropriate use of tamper-evident security labels (“stickers” to some!), when used with other security protocols, can greatly assist in maintaining end-to-end chain of custody over goods, valuables and sensitive items in your supply chain. This includes pharmaceutical and medicinal packages, goods for re-sale, food & drink items and many other types of goods which require protection from interference, loss or degradation.

In this article we look at the main types of tamper-evident labels; the many label customisation options and features available; and also explore how security labels can assist particularly in the pharmaceutical, food & drink and logistics sectors.

-

What is a security label?

First of all, what exactly is a security label? Security labels have special tamper-evident features so that they cannot be removed from a sealed surface without first becoming ‘void’, meaning that the label will physically and permanently change its appearance to indicate its removal. This informs a legitimate user that a sealed package or enclosure has been subsequently opened, interfered with or otherwise compromised during transit or whilst in storage.

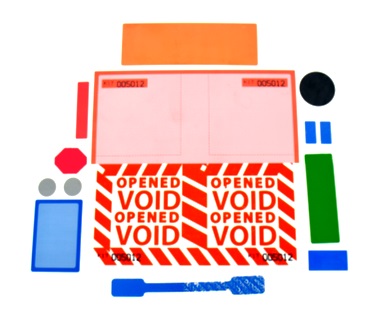

Security labels come in different material and adhesive blends. The first decision is generally to decide how the label will void, and what, if any residue message will be left behind on removal. There are two main options (permanent residue labels or no-residue labels), as well as other specialist labels to suit particular use cases, outlined below: -

| BASE MATERIAL | DESCRIPTION | eXAMPLE |

|---|---|---|

| Residue Unilabels | Residue UniLabels, otherwise known as ‘permanent void’ or ‘total transfer’ labels, leave a permanent void message on the sealed item itself, as well as voiding the surface of the label. This makes them useful on single-use packages such as test tubes, cartons and so on. |  |

| Non-Residue UniLabels | Non-residue UniLabels, otherwise known as ‘no transfer’ labels, only void themselves and do not leave any security residue on the sealed surface itself. This makes them particularly suited to short-term use on reusable packages such as tote boxes or crates. |  |

| Speciality Hybrid and Part-Residue Labels | Hybrid ‘rub off’ UniLabels offer a combination of reside and non-residue... a residue message which is left on the sealed item, but which can be rubbed off once no longer needed with no permanent damage. This is useful where the residue message is being used purely as a visual indicator, rather than as a security feature. |  |

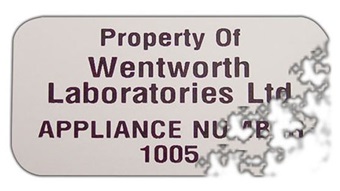

| Vinyl Destructible UniLabels | Vinyl destructible UniLabels, AKA ‘fragmentable labels’, have very strong adhesive which prevents the label being removed in one piece – the label will break into fragments when removal is attempted. They are suited for long-term applications e.g., the permanent marking of IT equipment & machinery. |  |

A note on surfaces

Not all surfaces are the same and the type of surface a label is applied to will affect how it performs. Many factors can influence how well a tape or label will stick to a surface; roughness, smoothness, porosity, coated, uncoated, cleanliness, flexibility, temperature conditions, moisture, and finally, surface energy of the surface. Labels will generally adhere very well to surfaces with a ‘high surface energy’ (hydrophilic surfaces). For trickier surfaces, we can provide specialist material/adhesive combinations which can suit niche applications, so please contact sales@universeal.co.uk to discuss your needs and we can provide advice and samples for you to assess.

-

Customisation Features

There are a number of features which can be incorporated into our UniLabel security labels, depending on the needs of your application. Below we outline some of the design features available and how they can assist in protecting your supply chains: -

| ILLUSTRATION | FEATURE | EXPLANATION |

|---|---|---|

| Custom Surface Markings | Security labels can be custom-printed with your logo, security warning, unique number / barcode & more. Such ‘overt’ security labels can act as a deterrent to anyone with bad intent, and also act to brand your packages.Alternatively, you may prefer to use ‘covert’ security labels – plain labels which aren’t obviously a security measure… until the label is removed (too late for the fraudster)! |

| Custom Void Messages | It is also possible to customise at the sub-surface level, i.e. the void design itself which appears through the label once removed, making your labels unique. This is particularly useful for covert labels, as once removed it may be useful to provide a custom message / security number to inform a legitimate user of a security-breach in transit. |

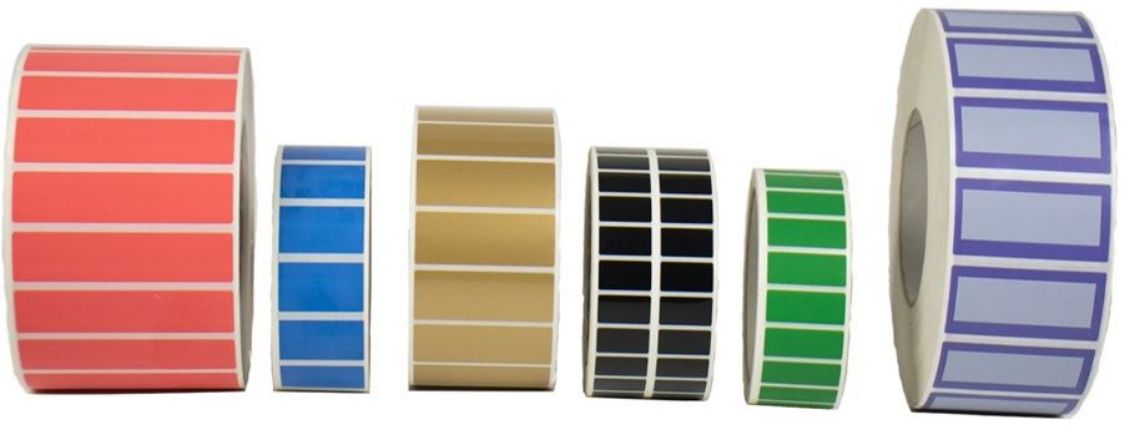

| Choice of Colours | There are a wide range of colours available, and we can pantone match where required. We can create labels which are as aesthetically pleasing as they are secure, and you can be sure they will provide the perfect conveyor of your brand message. |

| Security Cuts – Easy-Break Labels | By creating security scores in the mid-section of the label during the conversion process, we create a weak point in the label which allows its physical destruction when pulled apart. Security cuts can be useful where a label is being applied across on a door, cupboard or other access point where quick access is required without having to remove the label first. |

| NEL or WEL configuration | We can produce your security labels in Narrow Edge Leading (NEL) or Wide Edge Leading (WEL) labels. The choice is sometimes personal preference but can also be important when it comes to specifying labels which will work well in machine or hand-operated applicators. |

| Die Cuts | From dumbbell die-cut designs for use on vials and bottles... to large format square and circular labels for use on shipping pallets, we have hundreds of cutting tools in many shapes and sizes to suit the needs of the item being sealed. Every customer and every application is slightly different, so we can also commission a bespoke cutting tool if we haven’t got it already. |

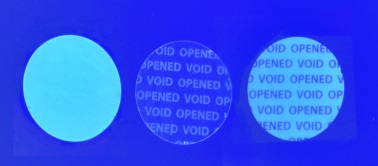

| Specialist UV Inks | In some use-cases, particularly for sensitive packages, it can be very useful for a tamper-evident label to void without telling the fraudster that they have been identified! We can do this with the use of specialist inks in the sub-surface void layer, which show only in the presence of UV light – and so revealing a fraudster’s suspicious activity! |

| Counterpart / “Dual Number” | Counterpart security numbers can be a simple and efficient way to maintain a record of security numbers as they are used – simply peel off the counterpart and attach to paperwork / manifests to cross-reference to the corresponding security label used to seal a package. |

| Finger Lift | ‘Finger lift’ labels do not have adhesive on the edges of the label, meaning they are easier to peel away from the liner when applying by hand. |

| Finish | Security labels are supplied matt as standard, but can also be produced with a gloss finish, providing an alternative aesthetic finish where this is preferred. |

| Paper Material | Last but not the least, and in an exciting addition to the range, we are now able to produce security labels in an entirely paper-based material and adhesive blend. Paper-based labels can help to reduce the use of single-use plastic in your supply chain without sacrificing security and chain of custody. |

Three Core Applications for Security Labels

Security labels are used for a vast variety of purposes, and every year we are amazed by the new and inventive ways our customers use security labels to keep their businesses and products safe and secure. Below we give a brief overview of their use in three sectors: pharmaceutical, food and drink, and logistics sectors.

- Security Labels for Pharmaceutical Uses

|  |  |

| Labels for applications on bottles and caps | Security labels on test tubes and sample vials and bottles | Security labels for Pill Boxes and other medicine products |

The overt use of tamper evident labels to seal pharmaceutical packaging adds to both distributors’ and consumers’ confidence in your brand by providing them with a reassurance that your product remains free of tampering or counterfeiting. Our UniLabel security labels can suit all layers of pharmaceutical protective and transit packaging, including pill boxes and secondary master cartons for distribution, all the way up to tertiary packaging such as pallets and large crates.

Our security labels are ‘anti tamper devices’ pursuant to the Falsified Medicines Directive, designed to protect consumers from the danger of counterfeit drugs and medicines. Security labels can be applied by hand or with automated machine applicators.

- Security Labels for Food, Drink and Pet Industries

|  |  |

| Security labels for ‘direct to consumer’ sealed packages | Guarantee of quality and authenticity for food items | Custom die cut labels to suit all types of containers & packages |

Similarly, security labels can also serve as a guarantee of authenticity and quality for food and drink sealed packages. They instantly provide a new layer of security adding to protection for all types of logistics: direct to consumer sales, takeaway deliveries and end-to-end food supply chains.

- Security Labels for Logistics and Transport Sectors

|  |  |

| Sealing boxes and cartons with security labels | Sealing air cargo shrink wrap with security labels | Large format security labels for securing pallet banding |

Security labels provide an instant level of security in all manner of logistics and warehousing operations, protecting you from pilfering and counterfeiting. Our UniLabels deliver ‘positive control checks’ throughout your distribution network and clearly flag instances of security breaches when they occur.

The use of track and trace features such as unique number / barcoding sequencing allows each sealed package to be traced throughout its journey, maintaining the chain of custody of valuable or sensitive cargo for you and your customers. Our UniLabel also work well in cold chain logistics, as labels function even in extreme temperatures as low as -80 degrees Celsius.

Contact us at sales@universeal.co.uk to discuss your needs today.